Most compliance failures in construction are not caused by poor intent or missing policies. They happen because organisations are trying to manage complex, high-risk, fast-moving operations using systems that were never designed to support that level of complexity.

Over time, this creates a widening gap between what a business believes is happening and what it can reliably prove is happening. On paper, processes look robust. In reality, evidence is fragmented, delayed or inconsistent. That gap is rarely visible day to day, but it becomes painfully clear during audits, incident investigations, and client reviews. It shows up as uncertainty. And uncertainty is where risk takes root.

Understanding why this gap forms requires stepping back from individual forms and procedures and looking at compliance as a system, not a checklist.

Compliance in construction is a system of interdependencies

Compliance is often broken down into discrete activities such as producing RAMS, recording training, monitoring HAVS exposure, inspecting equipment, and reporting incidents. These activities are then assigned to different owners and supported by different tools. While this structure appears organised, it ignores how tightly these elements depend on one another in practice. A worker’s training status determines what tasks they can perform. Those tasks dictate which tools and plant are used. Tool selection influences HAVS exposure and maintenance cycles. Maintenance status affects availability and programme planning. Each decision has a knock-on effect.

When systems fail to reflect these relationships, organisations are forced to manage compliance in fragments. Information is stored in different places, updated at different times and owned by different teams. No single person can see the whole picture, and no single system holds a definitive version of the truth. The result is not immediate collapse. Instead, confidence in the data slowly erodes. Once people stop trusting what they see, compliance stops informing decisions and becomes something that is assumed rather than verified.

Why traditional compliance models break under pressure

Most legacy compliance approaches rely heavily on people remembering to capture information and move it between systems. Workers are expected to complete checks, supervisors to upload forms, and office teams to reconcile records. This model assumes stable conditions and spare capacity. Construction rarely offers either.

Sites are dynamic environments. Priorities change constantly. People are interrupted. Problems demand immediate attention. In this context, administrative tasks are often deferred, even when everyone understands their importance. A plant check may be completed but not entered. A HAVS log may be updated later in the shift. A revised RAMS may be emailed but not stored centrally. Each individual delay feels insignificant. Collectively, they create gaps.

What makes this especially dangerous is that the organisation still appears compliant. Policies exist. Processes exist. Documentation exists. But the evidence that proves those processes are being followed consistently is incomplete or unreliable. This is how businesses drift into a state of “probably compliant”. And probably is not a defensible position when safety, legal responsibility, and reputation are involved.

The operational and cultural cost of fragmentation

The impact of fragmented compliance is often framed in terms of regulatory risk, but the operational cost is just as significant. Managers spend time chasing information rather than improving sites. Office teams reconcile spreadsheets instead of supporting delivery. Site teams are interrupted to resend documents or repeat checks. None of this work reduces risk. It simply compensates for weak infrastructure.

There is also a cultural consequence. When compliance feels slow, repetitive and disconnected from real work, people begin to treat it as bureaucracy rather than protection. Reporting becomes minimal. Learning from near misses becomes inconsistent. Over time, the organisation loses its ability to see patterns and address root causes. It becomes reactive rather than preventative.

Why digitising existing processes rarely solves the problem

A common response is to digitise existing paperwork. Forms become PDFs. Spreadsheets move into cloud storage. Email attachments are replaced by portals. While this can make information easier to store, it does not change the underlying structure. The same fragments still exist. They are simply digital.

True improvement requires a different starting point. Instead of asking how to capture information more efficiently, organisations need to ask how compliance fits into the flow of work itself. In other words, how can compliance happen naturally as part of planning, assigning, and carrying out tasks, rather than as a separate activity bolted on afterwards.

This shift moves the focus from document management to system design.

The role of a single source of truth

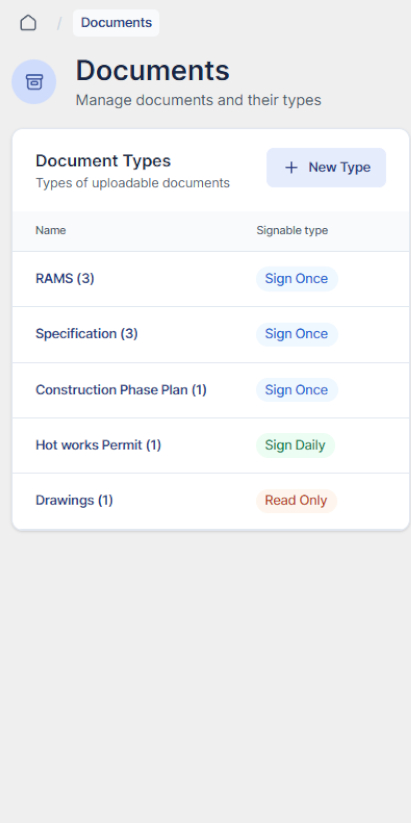

A modern digital compliance platform is built around the concept of a single source of truth. All relevant information lives in one connected environment and updates in real time. Worker profiles link directly to training and competencies. Competencies link to the tasks a person is allowed to perform. Tasks link to RAMS. RAMS link to plant and equipment. Plant and equipment link to inspection history and HAVS data.

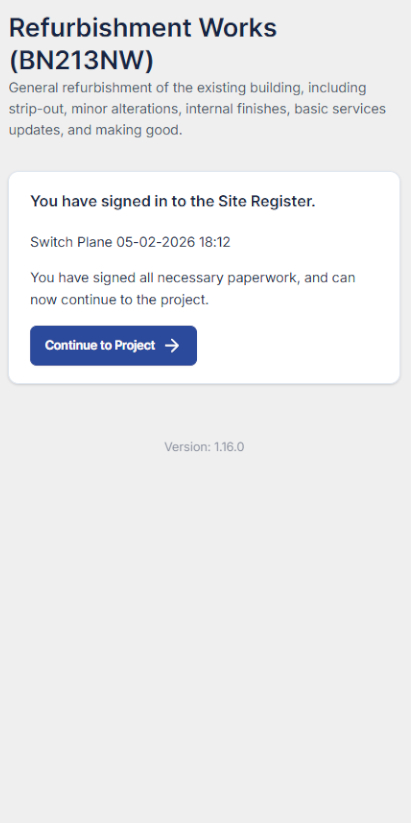

Because these elements are connected, rules can be enforced automatically. If training expires, the worker cannot be allocated to certain tasks. If a tool fails inspection, it cannot be booked out. If a RAMS is out of date, it cannot be approved. Compliance no longer depends on memory or goodwill. It is embedded into how the system operates.

This is the practical difference between paper compliance and provable compliance.

Designing for real site conditions

For connected compliance to work, systems must be designed for construction environments, not office desks. People are mobile. Connectivity is inconsistent. Time is limited. Interfaces must be simple. Actions must be quick.

Mobile-first platforms with offline capability, short forms, dropdowns, photo capture, and automatic timestamps dramatically reduce friction. Logging a check or recording an issue becomes a small part of the job rather than a separate task. When the right action is easy, people do it. When people do it consistently, data becomes reliable. When data is reliable, managers trust it.

This chain reaction is what makes digital compliance effective.

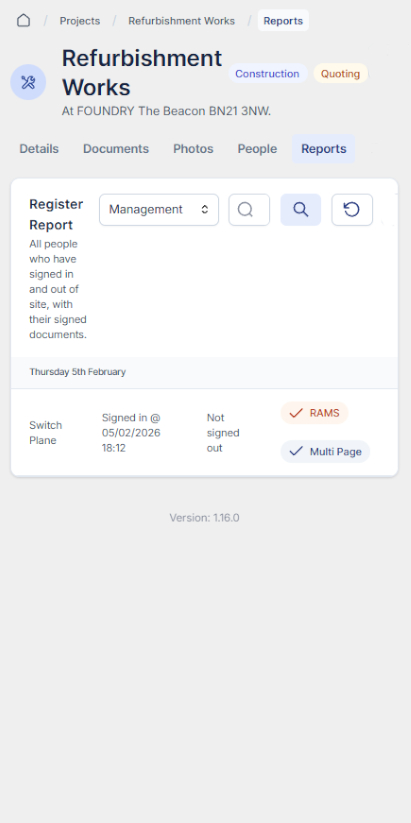

What managers gain from connected systems

For managers and directors, the most valuable outcome is visibility. Instead of relying on periodic reports, they can see live information about training coverage, inspection status, open actions, incident trends, and emerging risks. This enables earlier, more targeted intervention. Problems are addressed before they escalate. Resources are allocated based on evidence rather than intuition.

It also changes the tone of compliance conversations. Instead of asking whether processes are being followed, leaders can focus on where risk is increasing, where support is needed, and where systems can be improved. Compliance becomes a source of operational insight rather than a defensive exercise.

Why custom-built platforms matter

Off-the-shelf software is designed to meet the average needs of many industries. Construction businesses are rarely average. Each organisation has its own mix of trades, subcontractors, client requirements, and internal structures. When generic software does not quite fit, people create workarounds. Spreadsheets reappear. Shadow processes grow. Complexity returns.

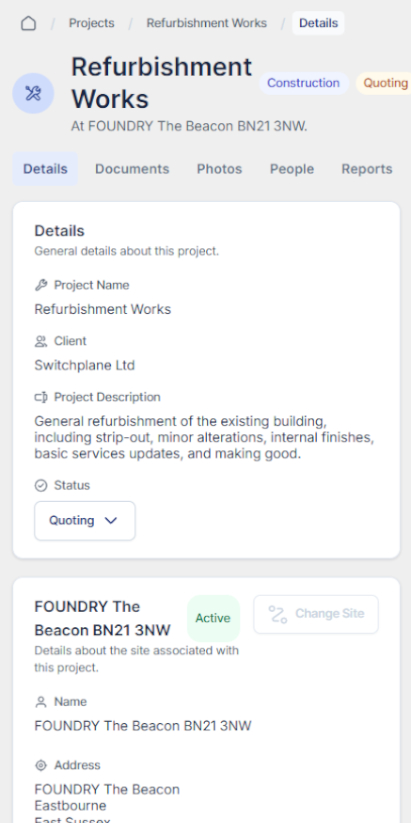

Custom-built platforms start with how the business actually works. Switchplane partners with construction organisations to map real workflows from office to site and back again, then designs systems around those workflows. This approach often allows businesses to replace several disconnected tools with a single platform that evolves as their needs change.

What this looks like in practice

Switchplane has worked with organisations such as Littlewood Fencing and Clarke Roofing to replace manual and spreadsheet-heavy processes with bespoke digital platforms. Across these projects, common outcomes include reduced administrative workload, improved data accuracy, and faster access to reliable information. More importantly, teams gain confidence that what they are seeing reflects reality. The improvement does not come from adding more features. It comes from aligning technology with how people actually work.

Most organisations do not need to fix everything at once. A practical starting point is to identify where fragmentation causes the most pain today, often training records, plant and equipment checks, RAMS distribution, or incident reporting. Mapping how information currently flows quickly reveals duplication, gaps, and delays. That map becomes the foundation for designing a single source of truth that can be built in stages. Progress matters more than perfection.

Compliance does not break because people do not care. It breaks because systems were never designed for busy sites. When compliance is embedded into everyday work and supported by connected digital platforms, good intentions become consistent, provable reality. That is the journey from paper to proof.

If your compliance still relies on spreadsheets, emails, and disconnected tools, it may be time to rethink the foundations. Switchplane helps construction businesses design and build digital platforms that fit how they really work.

If you want to explore what a single source of truth could look like for your organisation, get in touch.

Can we help you?

If you'd like to find out more about how to rethink digital in your business, get in touch today.

References

- Health and Safety Executive, Hand-arm vibration: advice for employers – Control of Vibration at Work Regulations 2005 guidance.

- Health and Safety Executive, Hand-arm vibration (HSE L140 guidance).

- Health and Safety Executive, Construction (Design and Management) Regulations 2015 (CDM 2015) overview.

- Health and Safety Executive, Construction (Design and Management) Regulations 2015 dutyholder summary.